Ceramic grade CMC

2017/7/29

1.Sodium Carboxymethyl Cellulose(CMC) for Ceramic/Porcelain Industry

Sodium Carboxymethyl Cellulose is widely used in ceramic industry.

Sodium Carboxymethyl Cellulose can be used as excipient and intensifier of the blank in ceramic industry, Sodium Carboxymethyl Cellulose can enhance the blank, a breakage rate if producer added suitable quantity of into the blank. In ceramic material, CMC can improve the glaze slurry, a flow and increase the smoothness and improve the quality of glazed surface.

Our brand “YUYU” CMC is taken as blank adhesive, plasticizer, glaze suspending agent and color fixing agent in porcelain/ceramic industry. Adding CMC to blanks will enhance blank adhesiveness (making it easily formed), have no residue, improve mechanical strength and reduce blank breaking rate. Adding CMC to glaze will enhance the binding of blanks and glaze, promoting glaze dispersion.

2.Commodity Name: Sodium Carboxymethyl cellulose

CAS No.: 【9004-32-4】

Molecular formula :[C6H7O2(OH)2OCH2COONa]n

Synonyms: Carboxymethyl Cellulose, Carboxy Methyl Cellulose, CMC, Sodium CMC, Na-CMC

HS Code: 39123100

3.Description

Sodium Carboxymethyl Cellulose is a cellulose derivative with carboxymethyl groups bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used as its sodium salt, sodium carboxymethyl cellulose.

4.Specifications

Ceramic Grade CMC

Types SpecificationC1C2C3C11C12C13

AppearanceWhite or Yellowish Powder

D.S≥0.9

Viscosity (mPa.s)10-5050-100100-300300-800800-1200≥1200

1% and 2% solution testing

PH (25°C)6.5-8.5

Moisture(%)≤7.0

Purity(%)≥98.5

Particle size (Sieving)Not less than 98% ( pass through 80 mesh )

5.Properties

A.CMC for ceramics features uniform distribution of substituents (carboxymethyl group) on the cellulose backbone. It produces fewer gel granules in glaze formulation.

B. It contains no colored impurity and is 100% combustible under firing condition, to ensure clean ceramic glaze.

| D.S | 0.5-0.7 | 0.5-0.7 | 0.5-0.7 | ≥0.7 | ≥0.7 | ≥0.7 |

| Viscosity (mPa.s) | 5-40 | 5-40 | 5-40 | 300-800 | 800-1200 | ≥1200 |

| 2% solution testing | 1% solution testing | |||||

| PH (25°C) | 8-11.5 | 8-11.5 | 8-11.5 | 6月8日 | 6月8日 | 6月8日 |

| Moisture(%) | ≤10.0 | |||||

| Purity(%) | ≥55 | ≥60 | ≥70 | ≥90 | ≥90 | ≥90 |

| Particle size (Sieving) | Not less than 98% ( pass through 80 mesh ) |

C. It can stabilize physical and chemical property of glaze formulation.

D. It can improve glaze adhesion and reduce glaze cracking.

E. It facilitates formation of a smooth dense glaze layer.

E. It can improve the rheological property of glaze formulation.

G. The glaze viscosity is proportional to the concentration of CMC added.

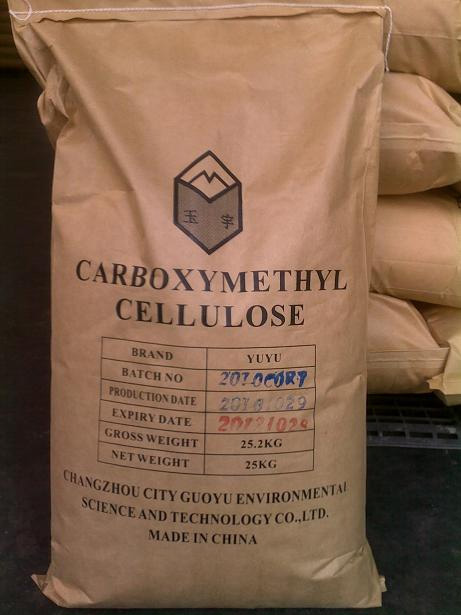

6.Package

Packing:25kg kraft paper bag, or other packing as clients request.

7.Storage

A.Store in a cool, dry, clean, ventilated environment.

B. Since the date of production, a preservation period should not exceed 4 years for the industrial product and 2 year for the product for pharmaceutical and food grade.

B. The products should be prevented from water and package bag damaging during transportation.

We can produce ceramic grade Sodium Carboxymethyl Cellulose with high purity, very high viscosity according to the customer's requirements

Victor Nutrition Enterprise Limited {Disclaimers} Anhui ICP 17017667

Tel:+0086 -18655172671

Email: calvinzuo@victor-nutrition.com

Address:Room 2527, Office C2, Jiayuan Plaza, intersection of Luzhou Avenue and Dongting Lake Road, Baohe District, Hefei City ,Anhui Province ,China