Mineral Processing grade CMC

2017/7/29

1.Sodium Carboxymethyl Cellulose(CMC) for Mineral Processing Industry

Sodium Carboxymethyl Cellulose is widely used in Mineral Processing Industry. For mining industry, “YUYU” CMC products helps company to constantly improve the cost efficiency of operations.

Sodium Carboxymethyl Cellulose is used in mining flotation to separate the metals and impurities as a high-purity, high-efficiency suspending agent.

2.Commodity Name: Sodium Carboxymethyl cellulose

CAS No.: 【9004-32-4】

Molecular formula :[C6H7O2(OH)2OCH2COONa]n

Synonyms: Carboxymethyl Cellulose, Carboxy Methyl Cellulose, CMC, Sodium CMC, Na-CMC

HS Code: 39123100

3.Description

Sodium Carboxymethyl Cellulose is a cellulose derivative with carboxymethyl groups bound to some of the hydroxyl groups of the glucopyranose monomers that make up the cellulose backbone. It is often used as its sodium salt, sodium carboxymethyl cellulose.

4.Properties

For mining industry, “YUYU” CMC products helps company to constantly improve the cost efficiency of operations. Additionally, as a globally recognized PAC/CMC manufacturer, “YUYU”ensure supply of process and performance chemical aids wherever operations are located, at comparative prices and stable quality. “YUYU” is also reliable suppliers able to adjust and customize products to fit various conditions and situations in mining processes.

For minerals such as those associated with the Copper, Gold, Nickel, Platinum Group Metals and Potash, “YUYU” CMC increase cost efficiency in the process of separating valuable mineral components from the gangue minerals.

In the process of Iron ore pellets. “YUYU” CMC products are used as binder and ensure outstanding green strength of the pellets during the process of pelletization. In comparison with commonly used alternative bentonite and hydrated lime, “YUYU” CMC brings more economical benefits and multi-functional advantages.

5.Package

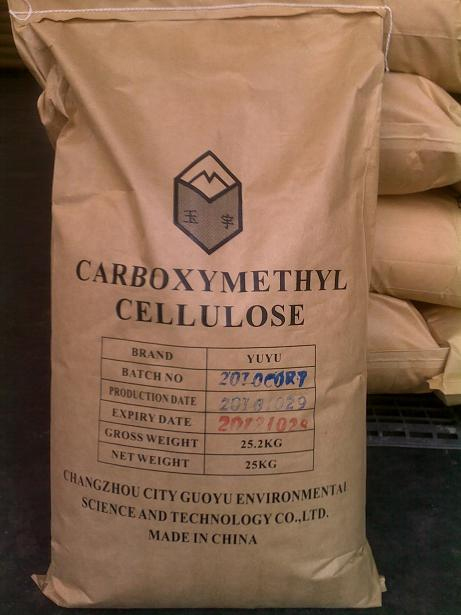

Packing:25kg kraft paper bag, or other packing as clients request.

6.Storage

1.Store in a cool, dry, clean, ventilated environment.

2. Since the date of production, a preservation period should not exceed 4 years for the industrial product.

3. The products should be prevented from water and package bag damaging during transportation.

Victor Nutrition Enterprise Limited {Disclaimers} Anhui ICP 17017667

Tel:+0086 -18655172671

Email: calvinzuo@victor-nutrition.com

Address:Room 2527, Office C2, Jiayuan Plaza, intersection of Luzhou Avenue and Dongting Lake Road, Baohe District, Hefei City ,Anhui Province ,China